Minumec, a leading company in the field of small parts and precision automatic turning, has recently moved from Lecco to Olginate. The new headquarters, consisting of more spacious, efficient and performing offices and sheds, represents an important step forward for the company.

With the passing of time and the addition of Giuliano and Giovanni Maglia, sons of the founder Giuseppe Maglia, to the company team, Minumec has become increasingly known for its excellent skills in the metalworking sector. The team and fleet grew accordingly, reaching a total of 40 equipment currently used for production. This allowed an expansion of the solutions offered by the company, but also led to the need to find a new, larger and more functional production space.

From here, the decision to transfer the company to Olginate, in a new plant that covers an area of 7,000 square meters and has a production area of 3,000 square meters.

The offices, which cover an area of about 250 square meters, are equipped with efficient workstations and an equipped meeting room.

The shed has been designed with three entrances, specific to each activity. The first two accesses allow to unload the goods in the two departments: the one dedicated to CNC machines, managed by Giuliano and that of multi-spindle lathes managed by Giovanni. The third passage allows the loading of the finished works for the delivery to the customer. This greatly improves logistics and organization, making workflow more efficient. The new headquarters also allows for a better connection between the various departments, so that they can communicate more efficiently and operate at their best.

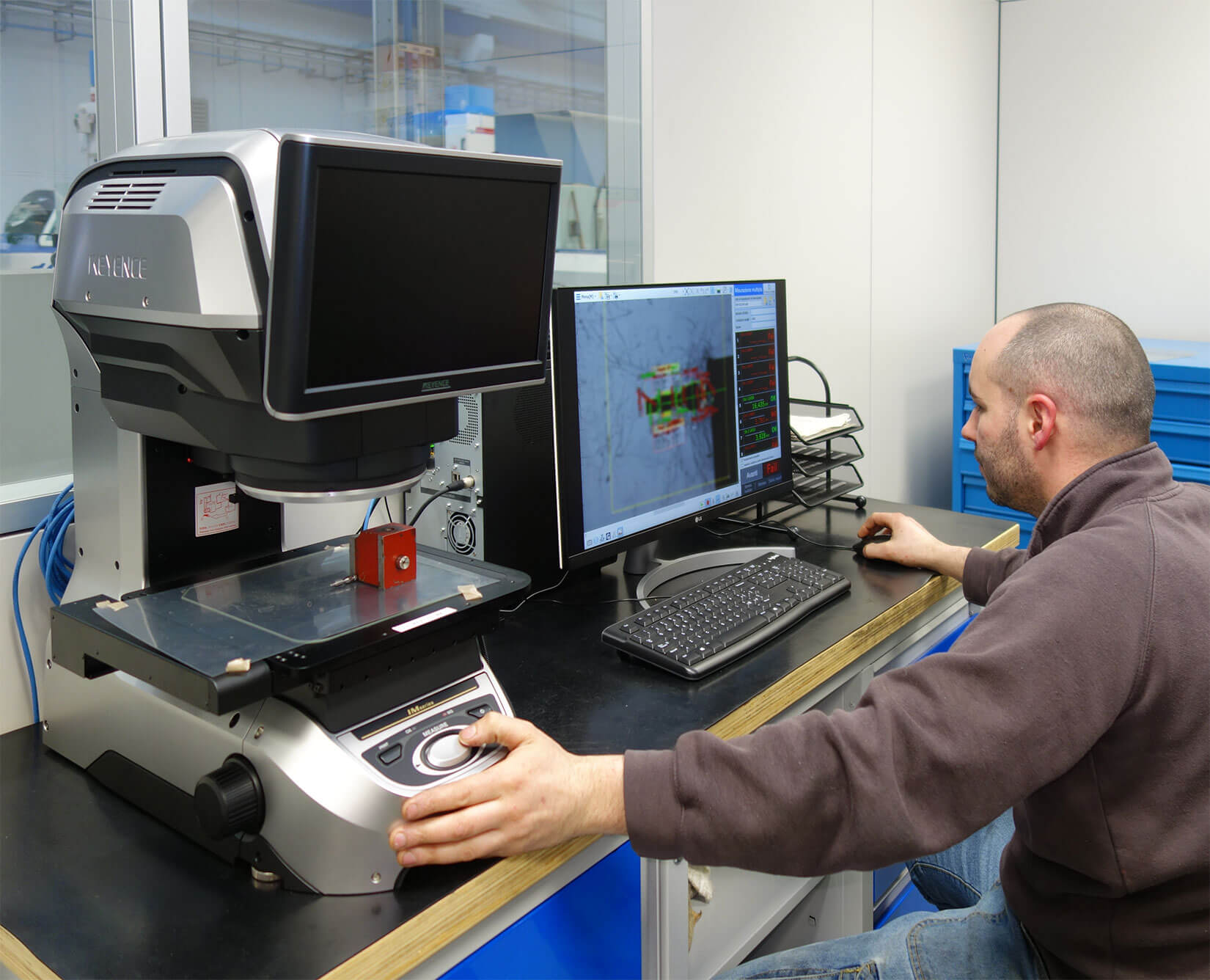

Technology, of course, also plays an important role in the new headquarters. For example, there is a platform weighing technologically advanced goods at the entrance, which allows you to better manage incoming trucks.

In addition, in collaboration with the Vicenza-based company FAMA, important choices have been made in the treatment of processing residues. The first, is the realization of a system of extraction and filtration of oily mists, which has involved the connection of multi-spindles of the department.

In addition, the focus has also been on the importance of the recycling of cooling lubricants and energy saving, to quantify in the future the CO2 emissions produced by the activities.

In fact, the condensation system of the steam sucked – the pre-filter with metal mesh model V4 – that captures the oil present in the vapors, recovering it continuously and sending it back inside the machine tool was also incorporated into the project. This allows constant liquid management and cooling lubricant recovery of more than 90%, with obvious economic advantages.

Finally, there is an innovative extraction system that optimizes the process of disposal of the metal chipboard generated during processing and the recovery of the oil used for production. All this helps to increase efficiency and reduce the environmental impact of the processes themselves.

The reuse of chipboard and oil in the processes of small parts and turning is an important aspect, to ensure the efficiency and sustainability of production activities.

The metal chipboard that is generated during production is moved to a separate location thanks to the aforementioned innovative suction system. This material is then processed and disposed of safely and responsibly. Similarly, the oil used during the process is recovered and reused, avoiding waste and thus reducing environmental impact.

A new headquarters, where Minumec can continue its thirty-year activity of metalworking

All these interventions demonstrate how Minumec is attentive not only to the quality and efficiency of its products, but also to the impact that its activities have on the environment. The reuse of chipboard and oil is an example of how technology can be used in an intelligent and sustainable way, to ensure an increasingly green and responsible future.

The work environment of the new headquarters, moreover, has been designed to be more spacious and bright, with the use of solar panels that collect energy, conveyed to allow the operation of both offices and machines. This makes it possible to optimise resource use and improve working conditions for employees.

Olginate, where the new headquarters are located, also has the characteristic of being surrounded by a landscape of great impact, which contributes to creating a pleasant and stimulating working environment.

Ultimately, the change of location of Minumec represents an important improvement for the company.

The new workspaces, more spacious, efficient and technologically advanced, will help improve the quality of work and increase the success of Minumec in the field of small parts and precision automatic turning.