In July of this year, Minumec took a significant step forward in the mechanical industry with the introduction of a new machine for stamped bushings. This innovation not only improves product quality but also revolutionizes manufacturing processes through Industry 4.0 connectivity, enabling remote monitoring and management of operations.

Replacing lead-free AVP steel and safer bushings

One of the key innovations is the replacement of lead-free AVP steel, a material that has limitations in both environmental sustainability and safety. The new machine allows for the use of alternative, more sustainable, and high-performance materials, contributing to the creation of safer and more durable end products.

As a result of this change, the produced bushings are stronger and more malleable, ensuring greater reliability and longevity over time.

A preformed bushing replaces the entire bar

Unlike traditional lathes, the new machine works with a pre-stamped bushing, eliminating the need to work directly with an entire bar. This process significantly reduces waste material and the need for additional operations, making production more efficient and sustainable.

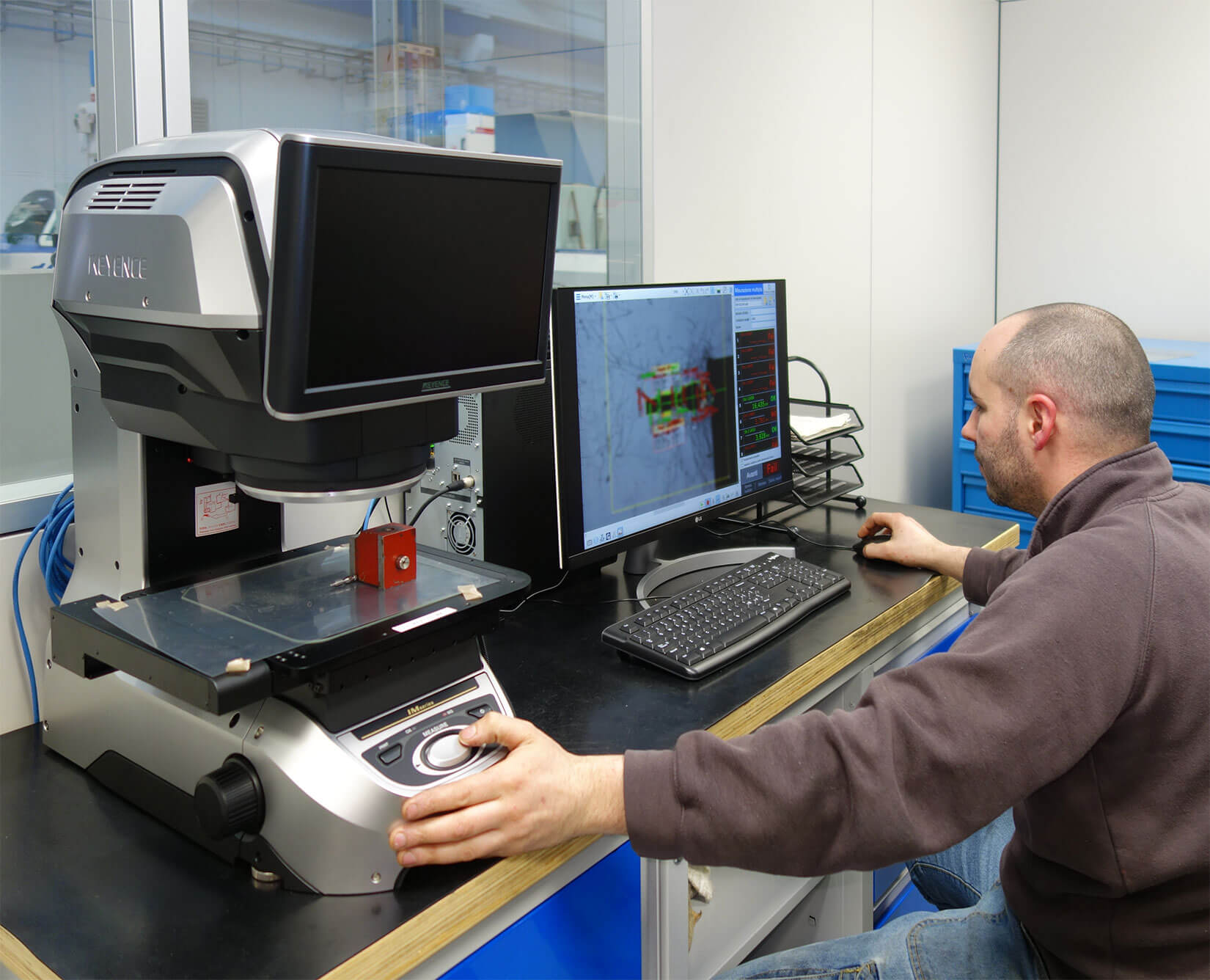

Advanced connectivity and remote management

Another distinctive feature of the new machine is its integration with Industry 4.0 systems. With advanced connectivity, it is possible to control and initiate operations remotely, optimizing time and increasing production efficiency.

Benefits of remote connectivity

- Real-time monitoring: Continuous process control with the ability to intervene immediately when needed.

- Operational flexibility: Remote management of operations from any location, enabling quick responses to customer needs.

- Process optimization: Data collection and analysis to improve machine performance and production processes.

- Reduced downtime: Preventive maintenance and remote diagnostics to minimize machine stoppages.

Specialized staff training

To fully leverage the potential of the new technology, Minumec’s staff underwent specialized training. This ensures optimal machine management and production that meets the company’s high-quality standards.

The future of bushing manufacturing

The introduction of this new machine marks a crucial step forward in the bushing manufacturing sector. By combining advanced technologies with a sustainable approach, Minumec is able to address current market challenges and anticipate future demands.

With this innovation, Minumec reaffirms its commitment to providing high-quality products and pursuing technological excellence. The new machine for stamped bushings allows us to deliver advanced, efficient, and sustainable solutions to our commercial partners.

Contact us for more information or to request a quote

If you would like more details about the new stamped bushing machine or need a customized quote for your needs, feel free to get in touch with us. Our team will be happy to provide you with all the necessary information and assist you in finding the most suitable solution for your business.

Contact us now!